The shipbuilding industry is a vital sector characterized by large-scale operations and mammoth structures. As a result, it demands heavy-duty lifting solutions capable of supporting various lifting and positioning tasks for massive ship components. Bossman Hydraulic Jacks, with their impressive capacity ratings of up to 150 tons and advanced hydraulic technology, provide the ultimate answer to the shipbuilding industry’s unique challenges.

In this comprehensive guide, we aim to showcase the remarkable potential of Bossman Hydraulic Jacks in reinforcing shipbuilding operations through their contributions to efficiency, adaptability, and safety. We will explore the diverse applications where these jacks demonstrate exceptional performance, from lifting hull sections and ship components to supporting vessels during maintenance or launching procedures.

Unique Challenges of the Shipbuilding Industry

The shipbuilding industry presents several specific challenges, making the need for resilient and powerful lifting solutions imperative. These challenges include:

- Massive Structures: Shipbuilding involves the construction and maintenance of vast vessels, such as cargo ships, cruise liners, and naval vessels, requiring lifting equipment with significant load capacities.

- Complex Construction Processes: Shipbuilding is a complex, large-scale operation with numerous tasks requiring adaptable and versatile lifting solutions.

- Strict Deadlines: With substantial investments and tight schedules, shipbuilding projects demand efficient lifting solutions that minimize downtime and accelerate project completion.

- Rigorous Safety Standards: Due to the risk of accidents and the high stakes involved in shipbuilding, safety is a top priority when selecting lifting equipment.

With their impressive capacities and advanced features, Bossman Hydraulic Jacks are uniquely designed to provide effective lifting solutions in the shipbuilding industry.

Key Applications of Bossman Hydraulic Jacks in the Shipbuilding Industry

Bossman Hydraulic Jacks play a vital role in several shipbuilding processes, showcasing their versatility and unrivaled lifting power. Some key applications include:

- Lifting Hull Sections: During ship construction, Bossman Hydraulic Jacks are employed to lift and position heavy hull sections, facilitating welding and assembly operations.

- Ship Component Assembly: Bossman Hydraulic Jacks can adeptly elevate and support ship components such as engines, propellers, and rudders, streamlining the installation and repair processes.

- Vessel Maintenance: When ships require maintenance, Bossman Hydraulic Jacks effectively raise and support the vessel, permitting efficient access to the hull or other components for inspection, repair, or cleaning.

- Launching Support: Bossman Hydraulic Jacks also find their place in ship launching preparations, providing the necessary stability and support as vessels are readied for sea trials or christening events.

Benefits of Bossman Hydraulic Jacks in the Shipbuilding Industry

Utilizing Bossman Hydraulic Jacks in the shipbuilding industry offers a range of significant advantages. Here are some of the most notable:

- High Lifting Capacity: With capacity ratings up to 150 tons, Bossman Hydraulic Jacks can easily manage the weight of enormous ship components and structures.

- Advanced Hydraulic Technology: Bossman Hydraulic Jacks’ hydraulic system allows smooth and controlled lifting, ensuring safe and accurate positioning during ship construction and maintenance operations.

- Enhancing Safety: Bossman Hydraulic Jacks come equipped with integral safety features such as overload protection, pressure relief valves, and stable bases, reducing the risk of accidents and injuries in the shipyard.

- Versatility and Adaptability: These jacks offer the necessary versatility to tackle a wide range of tasks in the shipbuilding industry, from heavy lifting assignments to more precise positioning tasks.

Optimizing the Use of Bossman Hydraulic Jacks in Shipbuilding Operations

To ensure the optimal utilization of Bossman Hydraulic Jacks in shipbuilding operations, consider these best practices:

- Select the Right Jack: Choose a hydraulic jack with the appropriate capacity, safety features, and adaptability to accommodate your shipyard’s specific lifting needs.

- Implement Regular Maintenance: Schedule routine maintenance checks and inspections to keep your hydraulic jacks in optimal condition, addressing issues like hydraulic fluid levels, wear and tear, and proper lubrication.

- Train Your Staff: Ensure your shipyard staff receives adequate training on safety protocols, proper jack operation, and maintenance procedures in order to maximize efficiency and reduce accidents.

- Use Quality Accessories: When using additional accessories, select high-quality products compatible with your Bossman Hydraulic Jack to guarantee safe and efficient lifting operations.

Enhancing Shipbuilding Operations with Bossman Hydraulic Jacks

Bossman Hydraulic Jacks offer robust and reliable heavy-duty lifting solutions for the shipbuilding industry, addressing unique challenges with their exceptional capacities, safety features, and versatility. With their impressive use range, Bossman Hydraulic Jacks empower shipyards to enhance efficiency throughout the construction and maintenance of vast vessels and ship components.

To get the most out of your Bossman Hydraulic Jacks, select the right model, implement regular maintenance routines, provide proper staff training, and use quality accessories. By following these guidelines, you can unlock the full potential of Bossman Hydraulic Jacks, bolstering your shipbuilding operations and setting the course for a thriving and successful future in this vital industry.

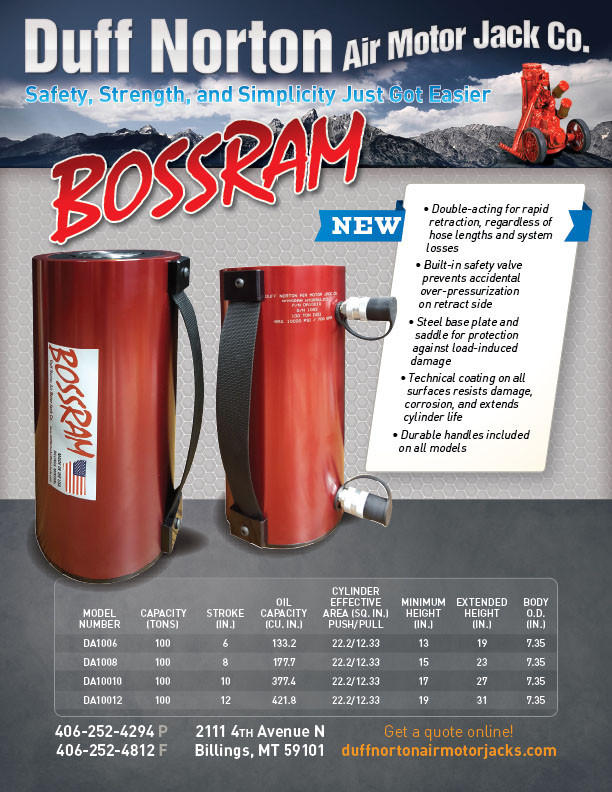

The Future of Heavy Duty Jacks

Are you tired of struggling with heavy lifting equipment in your industry? Do you want a reliable and efficient solution for your lifting needs? Look no further than Duff-Norton Air Motor Jacks. Our heavy duty jacks and lifting devices can handle up to 150 tons and are designed specifically for the railroad, mining, construction, and shipbuilding industries. Our products are durable, reliable, and built to last, so you can trust them to get the job done time and time again. Don’t let heavy lifting equipment slow down your production or put your workers at risk. Upgrade to Duff-Norton Air Motor Jacks today and experience the difference in efficiency and safety. Contact us now to learn more about our product line and how we can help you power up your lifting operations.