Efficiency and Safety in Heavy-Duty Applications with Bossman Hydraulic Jacks

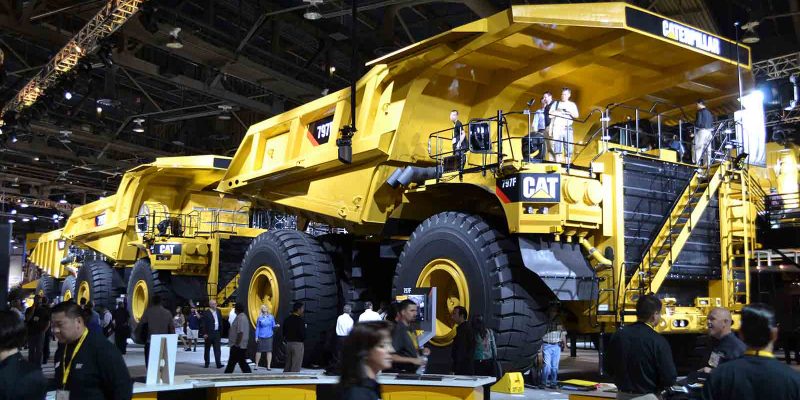

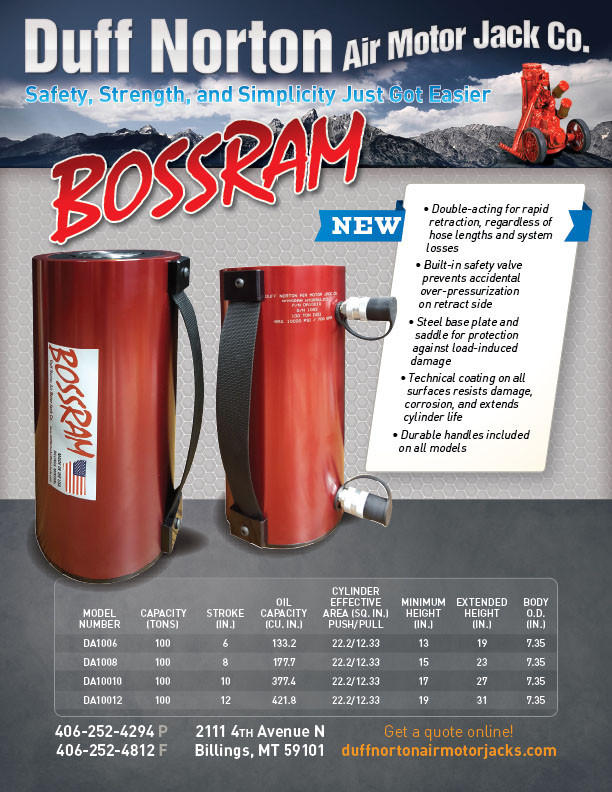

Having the right equipment can significantly improve efficiency, safety, and overall productivity when it comes to heavy-duty lifting tasks in industries like railroad, mining, construction, and shipbuilding. One solution for these demanding applications is the Bossman Hydraulic Jacks from Duff-Norton Air Motor. With capacities ranging from 50 to 150 tons, these heavy-duty lifting devices are designed to tackle the toughest jobs with ease and precision.

In this blog post, we will explore the features, capabilities, and benefits of Bossman Hydraulic Jacks, making them the ideal choice for challenging heavy-lifting scenarios.

-

Unmatched Power and Versatility

Bossman Hydraulic Jacks are available in three different capacity ratings—50, 100, and 150 tons—making them suitable for various industrial applications. From lifting heavy equipment during maintenance operations at a construction site to assisting with assembling massive ship components, these hydraulic jacks are up to the challenge.

The versatility of Bossman Hydraulic Jacks is further enhanced by their adjustable lifting stroke, allowing operators to tailor the device’s performance to suit the specific requirements of each job. This flexibility ensures that an optimal lifting solution is available for any heavy-duty task.

2. Robust Engineering for Lasting Durability

The durability and reliability of these hydraulic jacks are attributed to their high-quality engineering and construction. Bossman Hydraulic Jacks provide a long-lasting and dependable lifting solution, built with premium materials and tested to withstand the harsh conditions typically encountered in heavy industrial environments.

The rugged design of these jacks is complemented by the use of corrosion-resistant coatings and sealants, which help to protect the device’s vital components and ensure a longer operational life. With proper maintenance, a Bossman Hydraulic Jack can be a valuable asset for years.

3. Enhanced Safety Features for Maximum Job Site Protection

Safety is a top priority for any heavy-duty lifting operation, and Bossman Hydraulic Jacks are equipped with a range of features designed to protect workers and equipment.

For instance, the built-in safety relief valve helps to prevent damage caused by unintended overloading of the jack. The valve automatically releases pressure once the jack’s maximum capacity is reached, ensuring the device and its load remains secure.

Furthermore, each Bossman Hydraulic Jack is fitted with a locking collar mechanism, which provides a secondary support system during maintenance applications. This additional safety layer helps reduce the risk of accidents caused by sudden load shifts or equipment failure.

4. Easy Operation and Low Maintenance

Despite their impressive lifting capabilities, Bossman Hydraulic Jacks are designed with user-friendly operation and minimal maintenance requirements in mind. The simple and intuitive controls make it easy for operators to effectively manage heavy loads, while the built-in handle and compact footprint of these devices allow for straightforward positioning and transportation.

Maintaining a Bossman Hydraulic Jack is also a breeze, thanks to the device’s easy-access points for routine servicing. These features, combined with the jack’s robust construction and corrosion-resistant coatings, mean that little more than regular inspections and basic maintenance tasks are needed to ensure optimal performance over the long term.

Trust Bossman Hydraulic Jacks for Your Heavy-Duty Lifting Needs

Bossman Hydraulic Jacks from Duff-Norton Air Motor are the top choice for industries requiring powerful, versatile, heavy-lifting solutions. Their high capacity ratings, robust design, enhanced safety features, and easy operation make them the ideal choice for handling the most demanding lifting tasks in the railroad, mining, construction, and shipbuilding sectors. Investing in these reliable and efficient hydraulic jacks can optimize your operations’ efficiency, safety, and overall productivity.

Learn more about how Bossman 100-ton Hydraulic Jacks can benefit your business by visiting Duff-Norton Air Motor Jacks. Contact our knowledgeable team of experts for assistance in selecting the right lifting solution for your specific needs. Experience the power and reliability of Bossman Hydraulic Jacks for yourself and elevate your heavy-duty operations to new heights!