Mining is a demanding job that requires reliable and powerful tools to ensure everything runs smoothly. One of the most important tools in mining operations is the air motor jack. These heavy-duty devices can lift and move tons of material with ease.

Understanding the crucial role that air motor jacks play in mining helps us appreciate the complexity and importance of these tools. By enhancing safety, maximizing efficiency, and offering versatility, air motor jacks prove to be indispensable in the mining world.

Enhancing Safety in Mining Operations

Safety is a top priority in the mining industry. Air motor jacks play a significant role in enhancing safety during mining operations. These jacks use compressed air, which means there are no electrical parts that could produce sparks. This feature is crucial because many mining environments contain flammable gases. By using air motor jacks, we reduce the risk of fires and explosions.

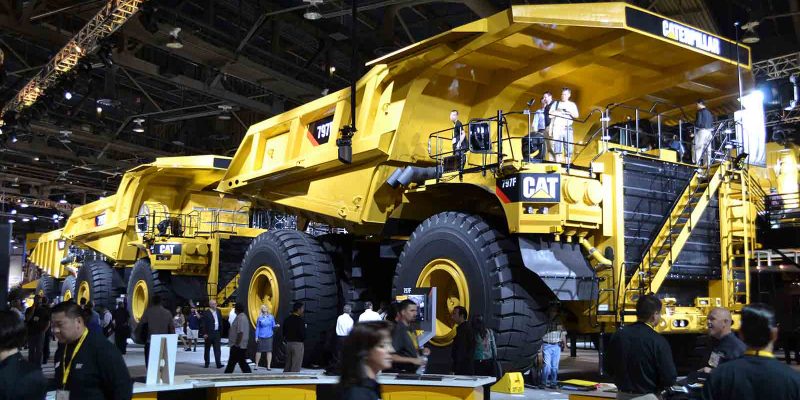

Another safety benefit of air motor jacks is their ability to handle extremely heavy loads. They can lift and support mining equipment that weighs several tons, which helps prevent accidents caused by manual lifting or unstable machinery. When lifting heavy mining vehicles or tunnel supports, air motor jacks provide the stability needed to perform tasks safely.

Additionally, air motor jacks are designed to be robust and reliable. Their sturdy construction minimizes the chances of mechanical failure, which reduces the occurrence of accidents. These jacks are also more predictable and controllable compared to manual methods, further enhancing safety on the job site.

Maximizing Efficiency and Productivity

Efficiency and productivity are critical in mining operations, and air motor jacks contribute significantly to both. By using compressed air, these jacks can lift and move heavy objects quickly and with less effort. This speed and ease of use mean that workers can complete tasks faster, leading to increased productivity.

Air motor jacks help streamline various processes in mining. For example, when installing or removing heavy equipment, these jacks make it possible to position and secure machinery accurately and efficiently. This precision reduces the need for adjustments and corrections, saving time and increasing overall efficiency.

In addition to speeding up tasks, air motor jacks also reduce the physical strain on workers. By taking on the heavy lifting, these jacks allow workers to focus on other important tasks, enhancing overall workflow. Less physical strain also means fewer injuries and less downtime, further contributing to productivity.

The reliability of air motor jacks ensures consistent performance, which is crucial for maintaining a steady workflow. By minimizing the chances of equipment failure and reducing the need for maintenance, these jacks help keep mining operations running smoothly and efficiently.

Versatility in Mining Applications

Air motor jacks are incredibly versatile, making them valuable tools for a wide range of mining applications. One of the main advantages is their ability to function in different environments. Mines are not uniform; they can be deep underground, within rocky terrain, or in confined spaces. Air motor jacks are adaptable to these varied settings due to their compact design and powerful lifting capabilities.

These jacks are also used for different types of tasks. They can lift heavy mining equipment, stabilize tunnel roofs, and even assist in the installation of supports. This versatility reduces the need for multiple specialized tools, simplifying the equipment required on-site. With fewer tools needed, the workspace is less cluttered, allowing for more efficient operations.

In addition, air motor jacks can work in extreme conditions where other lifting equipment might fail. They function well in both high and low temperatures and are resistant to harsh environmental factors such as dust and moisture. This makes them reliable tools for consistent use in demanding mining environments.

Reducing Downtime and Maintenance

One of the significant benefits of using air motor jacks in mining operations is their ability to reduce downtime and maintenance. Equipment failure and downtime can halt mining activities, leading to substantial financial losses. Air motor jacks are designed to be durable and require minimal maintenance, which helps keep mining operations running smoothly.

Air motor jacks have fewer moving parts compared to other types of jacks, which means fewer opportunities for mechanical failure. This reliability helps to ensure continuous operation, reducing the likelihood of unexpected breakdowns. By minimizing downtime, workers can focus on production goals without the interruption of frequent repairs.

When maintenance is necessary, air motor jacks are generally easier and quicker to service. Simple designs mean that parts can be replaced or repaired with minimal hassle. This ease of maintenance ensures that any potential issues can be resolved swiftly, getting the equipment back in operation as soon as possible.

Using air motor jacks, which are built to withstand the harsh conditions typical in mining, ensures equipment longevity. This longevity reduces the need for frequent replacements, providing long-term cost savings and contributing to more efficient mining operations.

The Essential Role of Air Motor Jacks in Mining Success

Air motor jacks are essential tools in the mining industry due to their ability to enhance safety, maximize efficiency, offer versatility, and reduce downtime and maintenance. By using these powerful devices, mining operations can run more smoothly and safely, ultimately increasing productivity.

Understanding the various applications and benefits of air motor jacks allows us to appreciate their importance in mining. These jacks not only make tough jobs easier but also ensure that operations are carried out more effectively and without interruption. From lifting heavy machinery to stabilizing tunnel structures, their role in mining cannot be overstated.

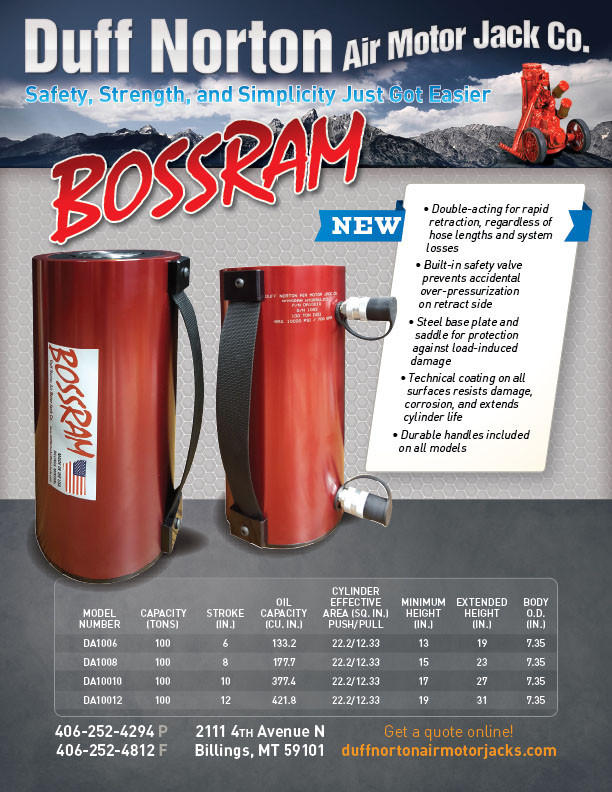

For reliable air motor jacks and expert advice, visit Duff-Norton Air Motor Jacks. Our high-quality products and knowledgeable team will help you find the perfect lifting solutions for your mining needs. Explore our range of air motor jacks today and see how we can support your next mining project!